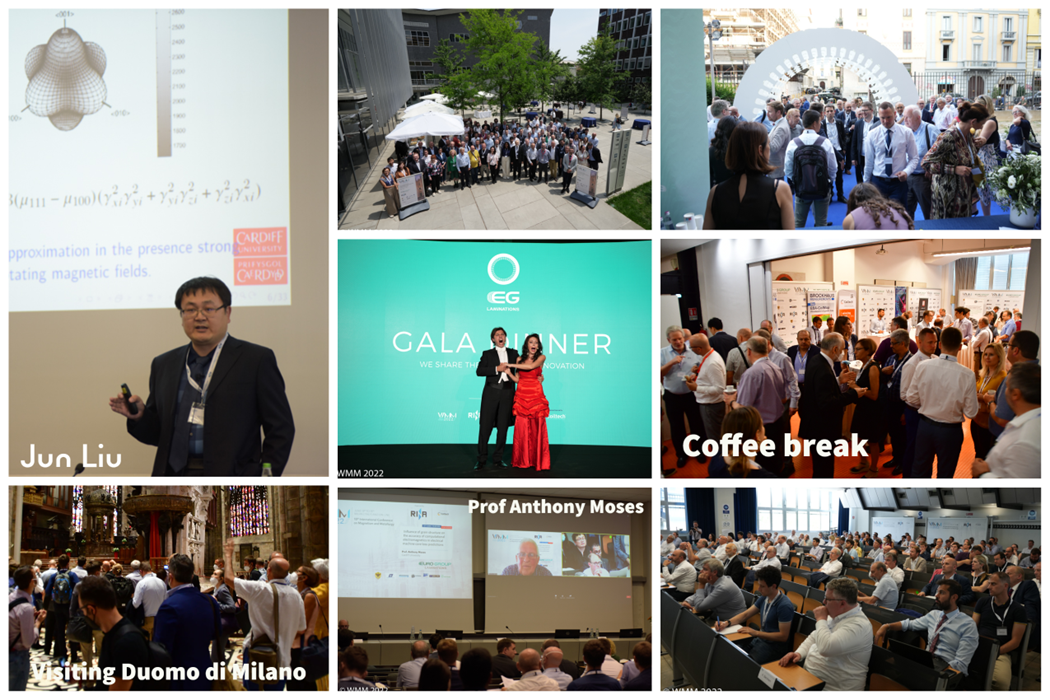

When Magnetism Meets Metallurgy – By Dr Jun Liu

22 August 2022“There is not only fashion, but also lamination”

‘Many people say fashion is the signature of Milan. I must say that is not entirely accurate – there is not only fashion, but also lamination’, said the CEO of Eurogroup Laminations at the gala dinner greeting the 190 delegates/guests of the 10th International Conference on Magnetism and Metallurgy (WMM’22). Eurogroup Laminations is an electrical steel maker based in Milan and the main sponsor of the WMM’22 conference. It was a good joke for the occasion and the audience and served its purpose well. More importantly, there was also an element of truth in that at least for these three days 13th-15th June 2022, when WMM’22 was taking place at the Polytechnic University of Milan. The conference was predominantly, if not all, about electrical steels, which are usually made into thin laminates. Electrical steel is indeed a perfect example product of the synergy between metallurgy and magnetism.

I was invited to give a lecture as an academic member of the MAGMA group at the School of Engineering of Cardiff University to disseminate my recent work on the modelling of magnetic anisotropy considering crystallographic textures [1] to the most relevant audience. One of the potential applications of my model, which is also the main topic of my paper for the conference, was to address the current issue that the magnetic anisotropy associated with crystallographic texture are often neglected or oversimplified in finite element modelling of magnetic devices. This can cause inaccuracy in the predictions of electrical steel performance, particularly in the presence of the complex electromagnetic fields and strong textures. I have demonstrated that the magnetic anisotropy associated with crystallographic texture significantly influence the distribution of the magnetic flux density and local permeability in the electrical steel components in a permanent magnetic electric motor. The animation below shows the predicted changes in the distribution of flux density and local effective permeability in the motor with the initial angle of the magnets. It can be observed there is a strong magnetic anisotropy in the stator laminate when the crystallographic texture of the electrical steels is considered. That is, higher permeability and flux density tends to distribute along or towards the RD direction (x axis). In contrast, isotropic material models, which are currently commonly used in FE modelling of electric motors, fails to capture the magnetic anisotropy. The work on the modelling of these effects on iron loss and the consideration of the hysteresis in the FE model is in progress.

………………………………………………………………………………………………………………………………………………..

“…equations used to theoretically calculate losses in grain-oriented SiFe have been developed making many assumptions which are not valid for today’s low loss, high permeability, anisotropic steels used under extreme magnetisation conditions.”

……………………………………………………………………………………………………………………………………………….

I will continue this article by summarising the main points of a few of the many fascinating presentations at the meeting.

Core loss is perhaps the most important property of electrical steels when it comes to their applications. There are increasing calls to make more accurate predictions of iron losses occurring in the laminated cores of novel designs of power transformers and highly efficient rotating electrical machines. Prof Anthony Moses [2] , Emeritus Professor at Cardiff University, gave an insightful and critical review of the issues in electrical machine core loss predictions and fundamental reasons with a focus on the influence of grain structure. His lecture illustrated how the accuracy of some measurement and prediction techniques are subject to commonly ignored effects associated with microstructures in electrical steels, particularly grain-oriented steel. For example, there is a dramatic change in the domain structure within a very small range of angles with respect to RD under rotational field, which may not be captured by standard rotational loss measurements and calculation. The domain wall movements are believed to account for the abnormal or excess loss.

It is the synergy between the metallurgy and magnetism that interests me most and, in my opinion, makes the WMM conference unique. Some lectures focus perhaps more on the metallurgy aspects, e.g., the characterization, control, modelling crystallographic textures and microstructures, with some correlations to magnetic propertiesl. Wolfgang Eggert et al [3], from Tenova LOI Thermprocess and RWTH Aachen University, reported a recrystallisation model for final annealing of non-grain oriented (NGO) electrical steel that can predict the texture in good agreement with the Electron Backscatter Diffraction (EBSD) data. The predicted textures could potentially be used as input in my microstructural permeability model to predict anisotropic magnetic properties, which, in turn, could be used in FE model of magnetic devices. Giuseppe Carlo Abbruzzese [4] from Spires Srl introduced their metallurgical models and corresponding commercialized software for predicting magnetic properties considering what looks like everything involved in the production of electrical steel. Interestingly in contrast, Leo Kestens [5] looked at only a single particular texture component, {311}<136>, of NGO steels.

…………………………………………………………………………………………………………………………..

A-parameter, A-parameter, A-parameter …

…………………………………………………………………………………………………………………………..

To my surprise the A-parameter have become a buzzword in this conference when it comes to the influences of the texture of electrical steels. It is a texture parameter that quantifies the density of easy directions within the sheet planes. The A-parameter appeared in a number of lectures being plotted against many other parameters e.g., magnetic flux density, anisotropy energy, orientation distribution functions (ODF) [6], or Schmid factor [7]. I also briefly reviewed it in my talk as a simple approach considering the texture effect compared to thet permeability models.

The WMM’22 conference features strong industrial support and presence with the speakers, delegates, and sponsors from a variety of industries accounting for a significant portion of the audience. They offered valuable inputs from the industrial perspectives on the research topics as well as market trends related to electrical steels. A key message I received and would like to pass on here is that there will be a surge in demand of electrical steels in the next couple of decades. However, there is a significant gap in the capacity of electrical steel production. We expect to see more research and collaborations to tackle these challenges soon and perhaps some exciting progress in the solutions to be reported in the next WMM conference.

[1] J. Liu and C. Davis, “Tensorial permeability microstructure model considering crystallographic texture and grain size for evaluation of magnetic anisotropy in polycrystalline steels,” Philos. Mag., vol. 101, no. 10, pp. 1224–1244, May 2021, doi: 10.1080/14786435.2021.1892229.

[2] A. Moses, “Influence of grain structure on the accuracy of computational electromagnetics in electrical machine core loss predictions,” in 10th International Conference on Magnetism and Metallurgy, 2022, pp. 37–53.

[3] W. Eggert, C. Wuppermann, M. Heller, T. Al-Samman, and S. Korte-Kerzel, “Recrystallization model for final annealing of non-grain oriented electrical steel,” in 10th International Conference on Magnetism and Metallurgy, 2022, pp. 319–333.

[4] G. C. Abbruzzese, “Use of Metallurgical Models to Predict GOES Mangetic Properties and to Design New Production Technologies,” in 10th International Conference on Magnetism and Metallurgy, 2022, pp. 223–247.

[5] L. Kestens and T. Nguyen-Minh, “The {311}<136> Recrystallization Texture Component of Non-oriented Electrical Steels,” in 10th International Conference on Magnetism and Metallurgy, 2022, pp. 265–272.

[6] J. Schneider and A. Franke, “Evolution of Grain Size and Texture at Final Annealing of Ferritic Non-oriented FeSi Steels,” in 10th International Conference on Magnetism and Metallurgy, 2022, pp. 145–173.

[7] B. Hutchinson and T. Nyyssönen, “Higher strength NGO steels for applications in motors,” in 10th International Conference on Magnetism and Metallurgy, 2022, pp. 93–108.