Conducting Net Zero research

31 July 2023

Cardiff University’s Translational Research Hub (TRH) works with industry to develop solutions to society’s grand challenges. At the recent TRH launch event, Professor Peter Smowton, Managing Director of the Institute for Compound Semiconductors, explained the role played by the tiny electronic chips in a big Net Zero future.

“I think when people say semiconductors it’s almost synonymous with silicon chips, and of course that makes a lot of sense because a lot of the advances of the 20th Century were built on silicon, particularly computer technology.

But silicon is reaching some really fundamental performance limitations. Already, many of the things we rely on in everyday life are only possible because of compound semiconductors: things like the internet, your smartphone, GPS, energy-efficient lighting.

Thankfully, for me, and for all of us working on compound semiconductors, most of the envisaged technologies going forward as well are also dependent on this key enabling technology.

Things like 6G wireless communication, ultrafast optical fibre, LIDAR for autonomous vehicles and for robotics, high power and high voltage switching for electric vehicles and for wind turbines, the Internet of Things, high-density data storage: all bring great opportunities around Net Zero and energy efficiency.

In fact, energy efficient lighting is one of the biggest things to have been delivered by compound semiconductors: the change from the filament bulb at one per cent efficiency, to the compound semiconductor LED lighting that is – in research at least – getting towards 90 to 95 per cent efficiency, is incredible.

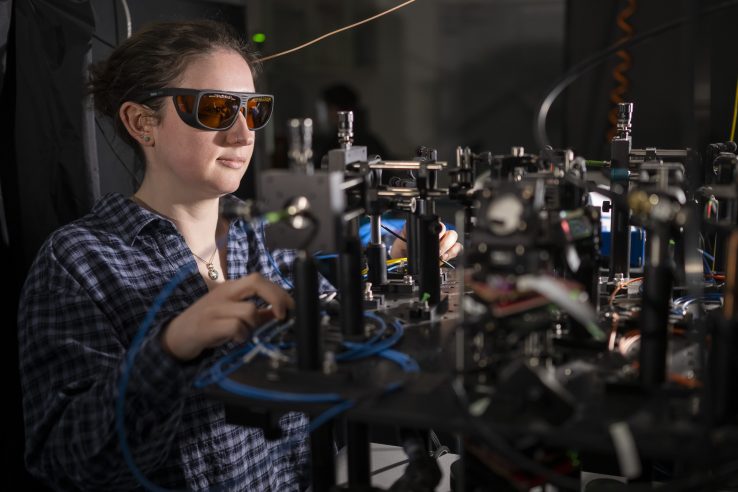

So, what is the Institute for Compound Semiconductors? The institute is essentially two different aspects in this building. The first is the cleanroom facility, which is a pay-to-use open access fabrication facility. You build compound semiconductors atom by atom and we get these two-dimensional wafers, and what the fabrication facility does is make the 3D structuring of those wafers by subtractive and additive manufacturing, essentially, to create the functionality that then supports the applications I’ve described.

Anybody in the UK can come and use it: academics, industry people – whoever wants to pay to use that facility can do so: they can pay our highly skilled engineers and technical staff to do that fabrication for them, or they can pay to come and use the equipment inside the cleanroom. And that’s really important for the vision: having those industry people and those academics together in that environment.

The vision for the ICS goes back to approximately 2013 when we were worried at the time about a problem that was put in a certain way: the so-called ‘Valley of Death’ between fundamental research and manufacturing: making money from that fundamental research, which then pays the taxes that go back into the investment in research, creating a virtuous circle.

Typically, as a researcher, I might take five years to come up with a fantastic solution. And then I would go to my industry partner and say: “Please manufacture that, make money and let’s complete this virtuous circle.

What they’d say to me is, “Oh my God, that’s so bespoke, that’s so hard to manufacture that actually either we can never do that, or it will take a lot of time and money to do all the production engineering necessary to make that work.”

So, the TRH helps us close the ‘Valley of Death,’ by allowing academics to think about how that solution will be manufactured right from the start. It’s about having academics working in a fabrication facility where, alongside research tools they are using, they have the production tools industry is using to do small-sale manufacture. It’s about having academics in the same environment as industry people doing small-scale manufacture so that they cross-fertilise ideas and cross-fertilise their thinking. And it’s about allowing academics to test a hypothesis, to see if it works. Researchers benefit from having a facility that is industry-standard, where research is reproduceable and works every time.

The Translational Research Hub makes everything work better. Here in this wonderful environment, we have brought together engineers, physicists, bioscientists and our colleagues in Cardiff Catalysis Institute who are really interested in surface science, which also really matters to compound semiconductors.

Thank you.”

Professor Peter Smowton

SmowtonPM@cardiff.ac.uk

For more information about the Institute for Compound Semiconductors, visit our website, or watch our film, below, about the newly launched ICS Cleanroom 👇👇👇.