Bronze Disease: Even Metal Gets Sick

24 January 2017

We are all familiar with the pleasing shininess of a new copper penny, and with how quickly this color becomes dull and matte simply from everyday use. This flat brown color doesn’t appear because the penny gets covered with dirt; rather, the copper surface has undergone a fundamental chemical change. The copper in the penny combines with oxygen in the atmosphere to form a layer of copper oxide. These thin corrosion layers do not obscure the details on the surface, or cause the coin any real harm.

Archaeological copper objects can undergo similar changes – or much more dramatic ones. Copper artifacts commonly undergo reactions with oxygen and carbon dioxide when they are buried, forming colorful copper oxides and copper carbonates. These copper carbonates are known in the world of mineralogy as malachite and azurite. Artifacts that are exposed to the air can react with sulfur dioxide to form copper sulfates, a product which should be familiar to anyone who has seen, for example, the green surface of the Statue of Liberty.

All of these products form relatively stable corrosion layers, often called a “patina”. They have incorporated copper ions from the artifact, thus reducing the amount of original metal, but they preserve the surface details of the object. The formation of copper oxide layers can even help to slow the formation of other corrosion products. Furthermore, if you excavate a copper artifact with only oxides or carbonates on it, the artifact will probably not disintegrate before your eyes before a conservator can get to it.

Sometimes, though, conservators encounter a much more insidious type of copper corrosion, dramatically known as “Bronze Disease.” When copper or its alloys are exposed to chloride salts, chloride ions migrate towards the metal surface and react with copper ions. This process forms a copper chloride mineral called nantokite underneath the copper oxides and carbonates. When a buried object is excavated, oxygen and water vapor from the air can get through overlying corrosion layers and react with the nantokite. When water reacts with nantokite, hydrated copper chlorides are formed, including atacamite, paratacamite and botallackite. These hydrated copper chlorides have a much higher volume than the nantokite layer. This sudden increase in volume causes the copper chloride to erupt through the overlying patina in bright blue/green powdery patches. Unfortunately, this reaction can continue until the original metal of the artifact is gone, leaving only a heap of blue dust.

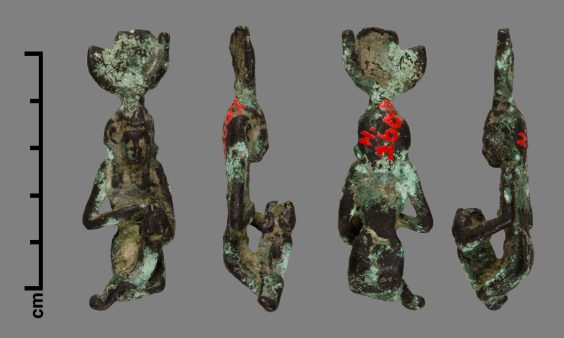

Unfortunately, copper alloy artifacts from archaeological contexts (i.e. buried) are often contaminated by chloride salts in the soil, making bronze disease distressingly common in museum collections. Museums across the UK inventory their collections, identifying problems like bronze disease. In many cases, they then choose to send their objects to the Cardiff University Conservation Department for treatment, saving their own resources and generously providing students with learning opportunities. The small statue pictured above is an alloy of copper and tin (a.k.a. bronze!) from the collections of the Bristol Museum.

The first time I looked at this small figurine, I was pretty sure that it had bronze disease – the powdery blue/green patches looked like open wounds in smoother black skin. We used the Scanning Electron Microscope (SEM) to take spectra of a few different types of corrosion on the figurine. This analysis (unfortunately) does not spit out the names of minerals (i.e. Cuprite, malachite, atacamite) – corrosion products are rarely that simple, anyway. It just tells you the amounts of different elements on the surface, and the conservator then has to interpret those numbers. All I needed to know was if chloride was present on the surface – it was!

Unfortunately, bronze disease does not have an easy cure. Conservation scientists are constantly experimenting with new methods to remove all trace of chlorides from the object. On the one hand, many of these treatments not only remove the chlorides, but also the protective stable patina. Since the chlorides often hide underneath the patina, removing them destabilizes any overlying layer. On the other hand, many are not effective at removing chlorides, so additional methods are necessary. The standard method that we have learned is to mechanically remove (with scalpels and picks) as much of the exposed powdery copper chlorides as possible. When this is finished, the object is coated with a substance called Benzotriazole (BTA), a corrosion inhibitor. It prevents bronze disease from forming by reacting with the copper surface of an object and suppressing the reactions that form harmful copper chloride compounds. A clear lacquer layer (often a common conservation-grade coating called Paraloid B72) is then applied to further protect the surface from future outbreaks of bronze disease.

I am still at the research and development stage with this bronze figurine. Before I can formulate and carry out a treatment plan, I need to have a full understanding of how and when each corrosion product formed. Since the bronze disease has already developed, I cannot return the figurine to the Bristol Museum with an attractive, uniform patina, but I can at least ensure that it is stable for the future.

References

Cronyn, J.M. (1990) The Elements of Archaeological Conservation. London: Routledge.

Scott, D.A. (2002). Copper and Bronze in Art: Corrosion, Colorants, Conservation. Los Angeles: Getty Publications.

Watkinson, D. (2016). Copper Corrosion Lecture. Cardiff University.

All photos taken by the author.

Comments

2 comments

Comments are closed.

- March 2024 (1)

- December 2023 (1)

- November 2023 (2)

- March 2023 (2)

- January 2023 (6)

- November 2022 (1)

- October 2022 (1)

- June 2022 (6)

- January 2022 (8)

- March 2021 (2)

- January 2021 (3)

- June 2020 (1)

- May 2020 (1)

- April 2020 (1)

- March 2020 (4)

- February 2020 (3)

- January 2020 (5)

- November 2019 (1)

- October 2019 (1)

- June 2019 (1)

- April 2019 (2)

- March 2019 (1)

- January 2019 (1)

- August 2018 (2)

- July 2018 (5)

- June 2018 (2)

- May 2018 (3)

- March 2018 (1)

- February 2018 (3)

- January 2018 (1)

- December 2017 (1)

- October 2017 (4)

- September 2017 (1)

- August 2017 (2)

- July 2017 (1)

- June 2017 (3)

- May 2017 (1)

- March 2017 (2)

- February 2017 (1)

- January 2017 (5)

- December 2016 (2)

- November 2016 (2)

- June 2016 (1)

- March 2016 (1)

- December 2015 (1)

- July 2014 (1)

- February 2014 (1)

- January 2014 (4)

I have analyzed many, many corrosion products; certainly in the thousands. The convenient and relatively inexpensive analysis protocols frequently detect and quantify only a range of heavier elements. Using methods that detect and quantify the lighter elements I found that with very few exceptions the corrosion products were not oxides but rather were hydrated oxides. The crystal structures of the hydrated oxides are markedly different from the pure oxides. The chemical properties are also different and that means that conservation procedures will also have to be different. For example, in particular circumstances an oxide on a bronze may appear as CuO.nOH.mH2O. Under other circumstances it might be Cu2O.nOH.mH2O. If a corrosion product formed and was maintained, in desert regions then I found the oxides to be CuO.nOH without the hydrated group. Now the OH and H2O groups are not coexisting with the metal “oxide”. There is often only a single crystalline form.

The heaviest guilt is borne by those relying on the EDS detector on their SEM. With both Cu and O detected they jump to the conclusion that the crystal structure and properties are those of the pure metal oxide. Take it from a metallurgist: it ain’t.

If it is of interest I will go on to point out how the “oxide’s” status within the metal makes it markedly different from the properties of bulk oxides.

Fred

Wow! That’s more information at once than I’ve gotten from many papers I’ve read about this! I will certainly have look more in depth into the preservation of these different products. And I may end up citing you in my final write-up. 🙂 I’ll keep in touch about how the project turns out!